Chainless pallet indexing system Oval screen printing machine

Printing Technology X Printing Technology

Why Go For Oval Type Screen Printing Machine

More Pallet Stations Available Than Circular Type Screen Printing Machines (Carousels)

Oval Screen Printing Machines can be extended, allowing for more pallet stations than traditional circular type printing machine, meeting the requirements of a wide variety of printing technique and various kinds of chemicals.

Flexible Design

Customers can increase the number of pallet stations, flash cure stations and open stations, to meet the requirements of a wide variety of printing procedures.

Running as Multiple Production Lines: (Double Production)

The machine has the capability to run two or more consecutive designs at one time, increasing production rates and reducing set up time.

- When running as 2 production lines, each line 5 colors

- When running as 4 production line, each line 2 colors

Application 10 Printing Heads with 34 Pallet Stations

More Flexible Arrangement than Carousel Machine:

- Printing heads can be pulling up to gain more space for Curing/Cooling/Inspection Purposes

- Customers can create their own application arrangements to meet requirements

No Sacrifice The Number Of Printing Colors (Stations)

With standard circular machines (carousels) there is a limit to the number of stations that can be made available. This is due to the physical size of the machine becoming unmanageable beyond approximately 22 stations. Because of the linear design of Acme Oval Machines, this is no longer a problem. Acme Oval Screen Printing Machines are modular in design and can be produced in up to 76 stations, resulting in an extremely flexible machine, able to cope with all ink systems and process’s.

To Satisfy For Rubber Paste Printing

Due to the inherent problems associated with printing water-based and rubber inks, Oval Machines remain the best method of printing using these ink systems. Due to the large number of stations available, this allows for the ability to have multiple flash and cool down stations, eliminating ink ‘pick-up’ which is usually the result of the flash cured design remaining tacky as it travels under the next screen. This also enables greatly improved production speeds by eliminating the need to use a dwell time to allow the print to dry between colors.

Efficient Quality Control

Due to the huge number of pallet stations available on our range of Oval Machinery, this allows for easy visible access to the printed garment, reducing the amount of defective prints and alerting the operator to the problem at the time. Because of the nature of circular printing machines, the defective print is usually only noticed once it arrives at the off-load station, resulting in defective prints on every remaining pallet.

Take Up Less Space Than Carousel Type Machine

Due to the huge number of pallet stations available on our range of Oval Machinery, this allows for easy visible access to the printed garment, reducing the amount of defective prints and alerting the operator to the problem at the time. Because of the nature of circular printing machines, the defective print is usually only noticed once it arrives at the off-load station, resulting in defective prints on every remaining pallet.

Features

Chainless pallet indexing system

Production capacity can be reached up to 720 pcs/hr

All servo driving system

For cut pieces and ready garments printing purpose

For normal size printing area

New design for jumbo size machine, it can be let people stand

Inside the machine to help lay down fabrics.

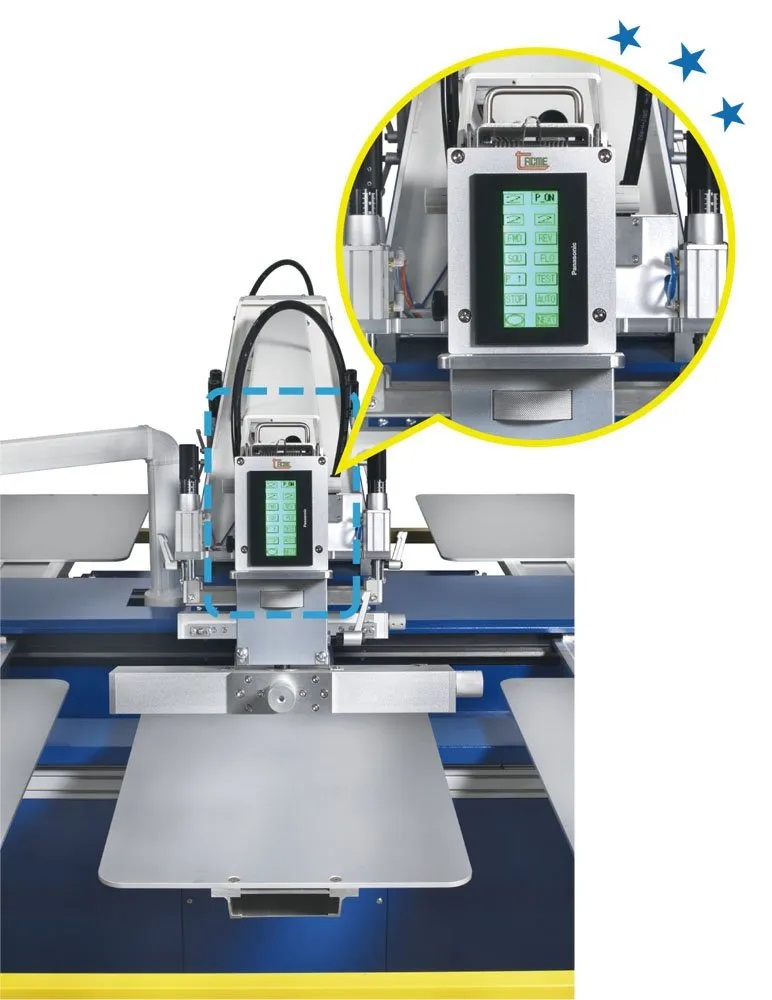

New Design-multifunction monitor

ACME integrated some main functions from central monitor to small monitor on each printing head. Easy for operators to change the speed of the machine, printing mode, printing speed, printing direction and other functions on the small monitor of the printing head. Either side of the operators can also operate the machine nearby and can exam the printing effect at any time without having to return to the central monitor for operation.

Digital central control monitor

Japan Kobelco solid aluminum alloy pallet

Printing pallet adopt with solid aluminum alloy, made by Japan Kobelco, features even surface and stable material, and temperature resistant to 250~300 degree.

In normal operation, guranteed no distortion for more than 12 years.

Specifications

All servo driving system

① Servo-dirve index

② Servo-dirve printing head

Central control panel

① Touchscreen controlled

② Multiple languages

③ Multiple-print with no raising the screen (hand printing mode)

④ Skip printing mode

⑤ High density printing mode

⑥ Troubleshooting system

⑦ Multiple printing stroke capability:1-9 times

⑧ Other function concerned

Bidirectional printing function

Independent control panel on each printhead

Sequential start and stop control system

Flash-cure power distrbution with built-in plug on all printheads

Index precision: +/-0.02mm

8 colors 28 stations

Printing area: 500mmx700mm

12 colors 40 stations

Printing area: 500mmx700mm

16 colors 52 stations

Printing area: 500mmx700mm

20 colors 64 stations

Printing area: 500mmx700mm

24 colors 76 stations

Printing area: 500mmx700mm

Get in touch with us

we believe that the strength of any project begins with the quality of its equipment and materials